Membrane filtration

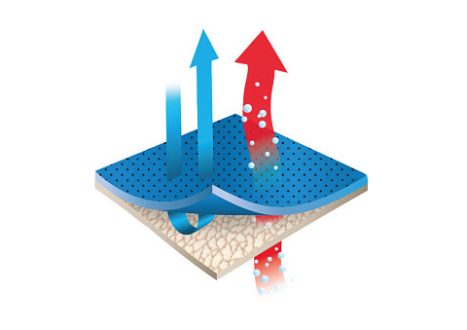

The selection of the appropriate membrane filtration process to achieve the desired level of efficiency will depend on the current level of water contamination and the degree of purification required. Membrane filtration is divided into four groups according to the size of the membrane pores: microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Membranes differ from each other in the size of impurities (particles, molecules or microorganisms, viruses) that are retained.

The type of membrane is selected based on the type of pollutants present in the water:

Reverse osmosis (RO) is one of the most advanced filtration technologies for deep water desalination. This method uses semi-conductive membranes with a pore size of about 0.1 nanometers. Under the action of high pressure, water molecules and some solutes (which are smaller than the pore size of the membrane) pass through the membrane, while other impurities are retained.

Nanofiltration is a relatively new filtration method that is used for softening and removing disinfection products and organic substances from slightly polluted water (eg surface water). The pore size of nanofiltration membranes is between 1 and 10 nanometers. Recently, nanofiltration is increasingly used not only for water purification but also in other industries (e.g. in the food industry – milk processing or juice production processes).

Ultrafiltration is a membrane filtration process, during which substances under pressure are separated through a semi-permeable membrane with a pore size of 1-100 nanometers. Solid particles and high molecular weight substances are retained in the concentrate, while water and low molecular weight substances pass through the membrane and remain in the filtrate. Drinking water is obtained after removing impurities from surface water. The efficiency of pathogen removal reaches 90-100%. In industry, this separation process is mostly used for the concentration of macromolecular (103 – 106 Da,) mostly protein solutions, as well as for blood dialysis.

Microfiltration – in most cases, this process is used for the primary treatment of water before it is fed to reverse osmosis units. During filtration using microfiltration membranes, solid particles that are not dissolved in the liquid are removed, while dissolved molecules and ions are allowed to pass through. The microfiltration membranes have a pore size ranging from 0.1 to 10 micrometers.